Plastic injection moulding is a process which is used

to produce a variety of plastic products. Companies that are dedicated

to manufacturing plastic using this process are able to mass manufacture

a variety of plastic products that are designed to your requirements.

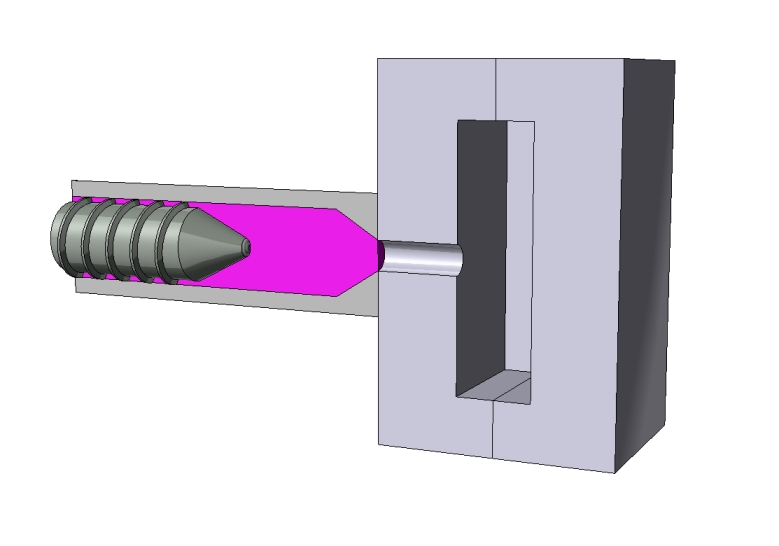

Plastics Injection Moulding process comprises of four steps, take a look:

Clamping -- During this period, the plastic is

held securely by way of the hydraulically operated clamping unit which

forces the mould and places pressure to help keep it strongly shuts

while being treated.

Injection -- The polymeric material that is

obtainable in powder form has moved into the plastic injection moulding

unit by the plastic injection system for melting. Once it is melted, it

is effectively injected into pressure packs within a certain

temperature.

Cooling -- The melted materials solidifies

soon following a pre-determined cooling time. As the plastic cools down,

it assumes the form of the sought after component. The cooling down

procedure is frequently affected from shrinkage which is adjusted at the

injection stage where additional material is allowed to run into the

mould.

Ejection -- This uses a certain process to

drive the element out from the mould. Certain force has to be applied

because the component adheres to mould. A release agent may be sprayed

on the surfaces of the mould to aid ejection.

At Longara Plastics, you're assured that you will be provided with an Plastic injection moulding device as well as an whole service necessary for your business development.

No comments:

Post a Comment